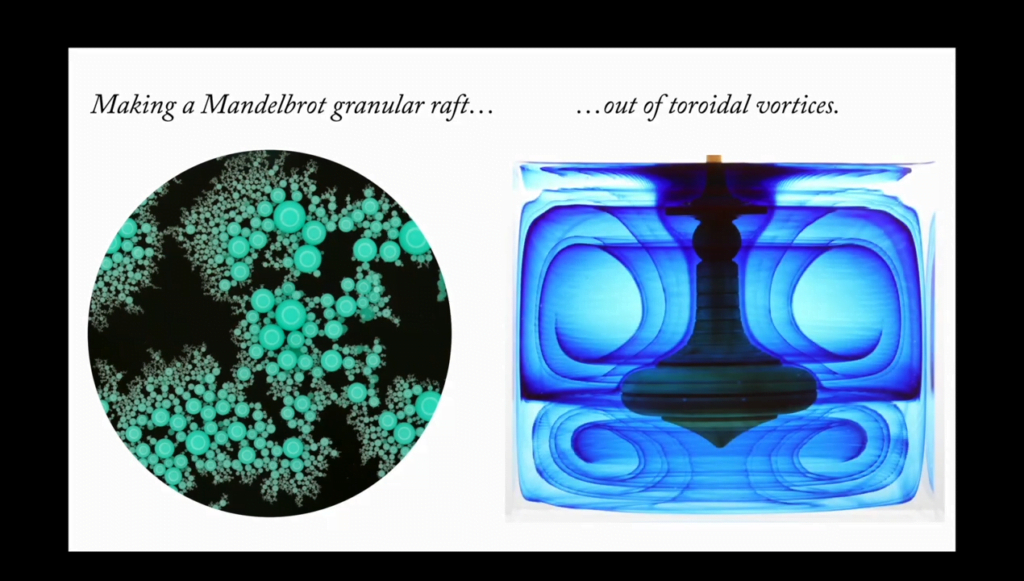

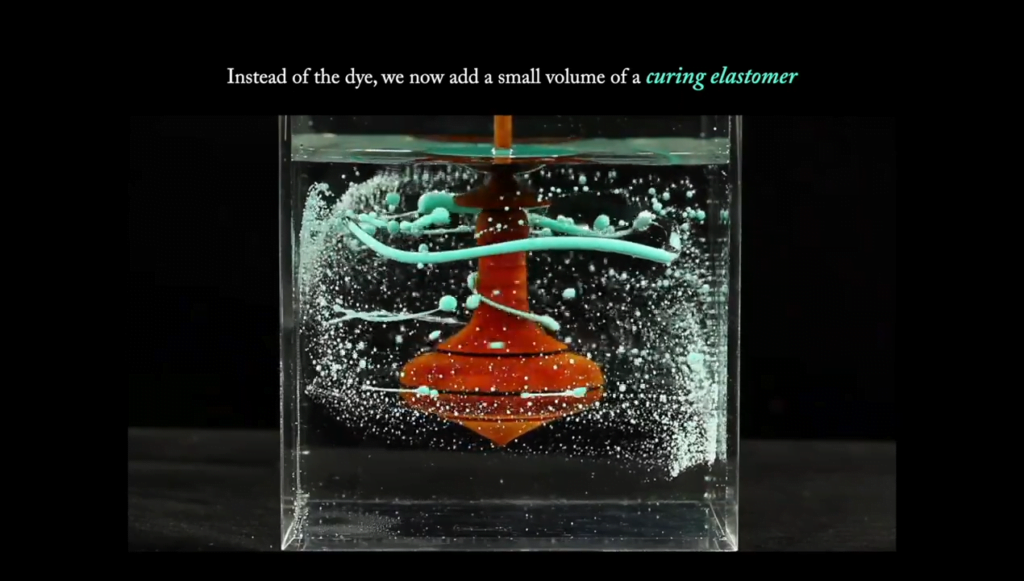

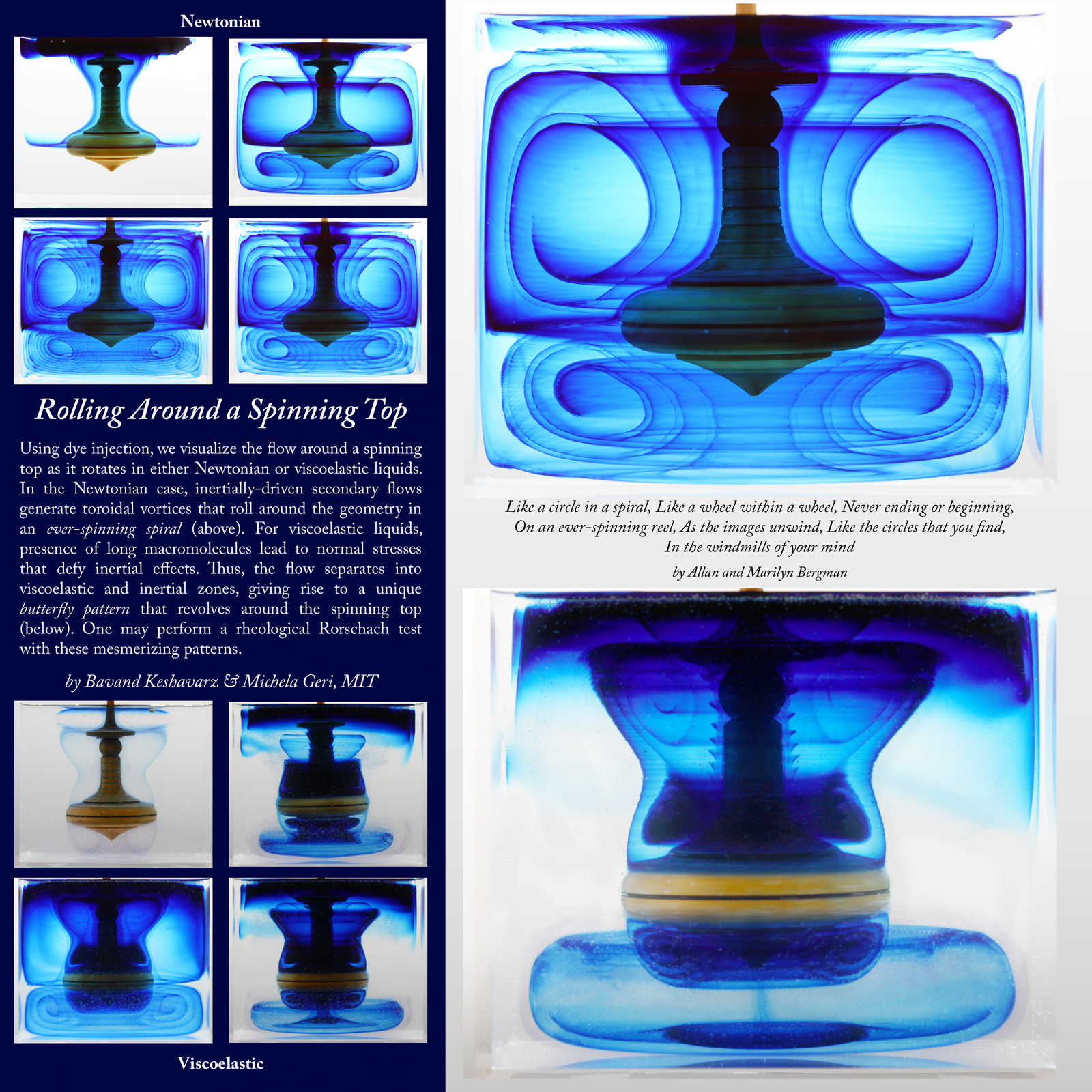

File this one under Cool Things I Would Have Never Thought Of. In this video, researchers play around with the flow around a spinning top and end up creating a fractal, granular raft. By immersing a top in dyed fluid, they show the toroidal vortices that form around the spinning toy. Then, instead of dye, they add a stretchy elastomer compound that cures over time. The elastomer stretches into thin ligaments in the swirling flow around the top. Eventually, it breaks apart into spherical drops of all different sizes.

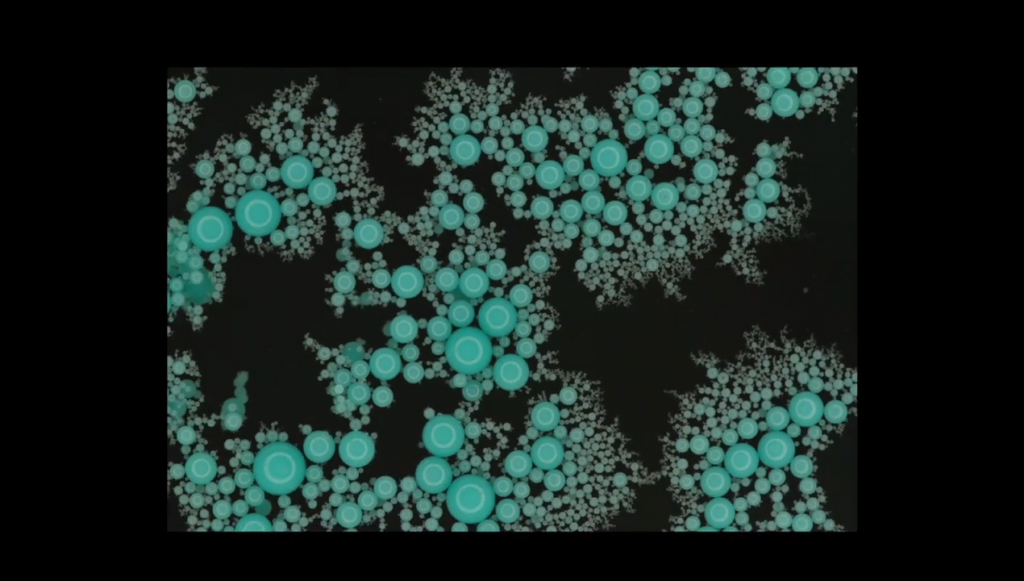

Once the top is removed, the elastomer drops slowly float to the surface. Surface tension and the Cheerios effect draw the drops together, and because of their many sizes, the rafts that form are fractal. (Image and video credit: B. Keshavarz and M. Geri)