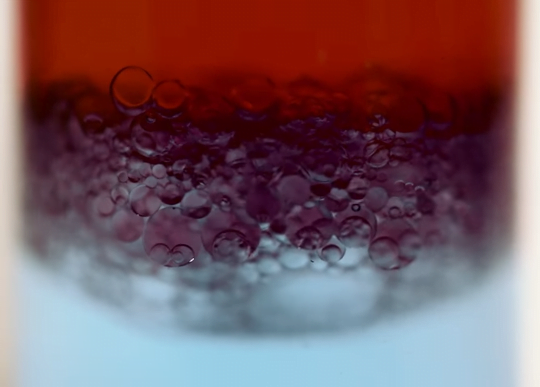

In cooking, sometimes the simplest recipes are the toughest to master. Cacio e pepe — a classic three-ingredient Italian pasta — is an excellent example. Made properly, the sauce of cheese and black pepper combines with starchy water to coat the pasta in a uniform, cheesy sauce. Or, if you’re me, you wind up with a pasta sauce flecked with stringy clumps of melted cheese. Fortunately for those of us who have yet to master this one, a new research paper has us covered with tips to make the perfect cacio e pepe.

The key to that elusive silky sauce, they found, is the starch – water – cheese combination. Your water needs just the right amount of starch — they found that between 1 – 4% starch by (cheese) mass worked. If the starch concentration is too low (which can easily happen in pasta water), you’ll get the clumpy cheese mess that so frequently happens in my kitchen. Temperature is also critical; if the water is too hot when it’s added, then it can destabilize the sauce. Check out the pre-print’s Section V for the scientific, supposedly foolproof, recipe. I know I’ll be trying it! (Image credit: O. Kadaksoo; research credit: G. Bartolucci et al. pre-print; via APS News)