Today’s video is a little different: it’s an inside look at a butter-making shop in France that uses traditional nineteenth-century methods to process the butter. Watching workers fold and shape 50 kilos of butter is mesmerizing, and it highlights the amorphous, pseudo-fluid nature of the butter. Yes, the butter holds its shape like a solid, but it’s a soft solid at best and certainly shows fluid-like qualities when force is applied. A word of warning: you might not want to watch this on an empty stomach! (Image and video credit: Art Insider; via Colossal)

Tag: non-Newtonian fluids

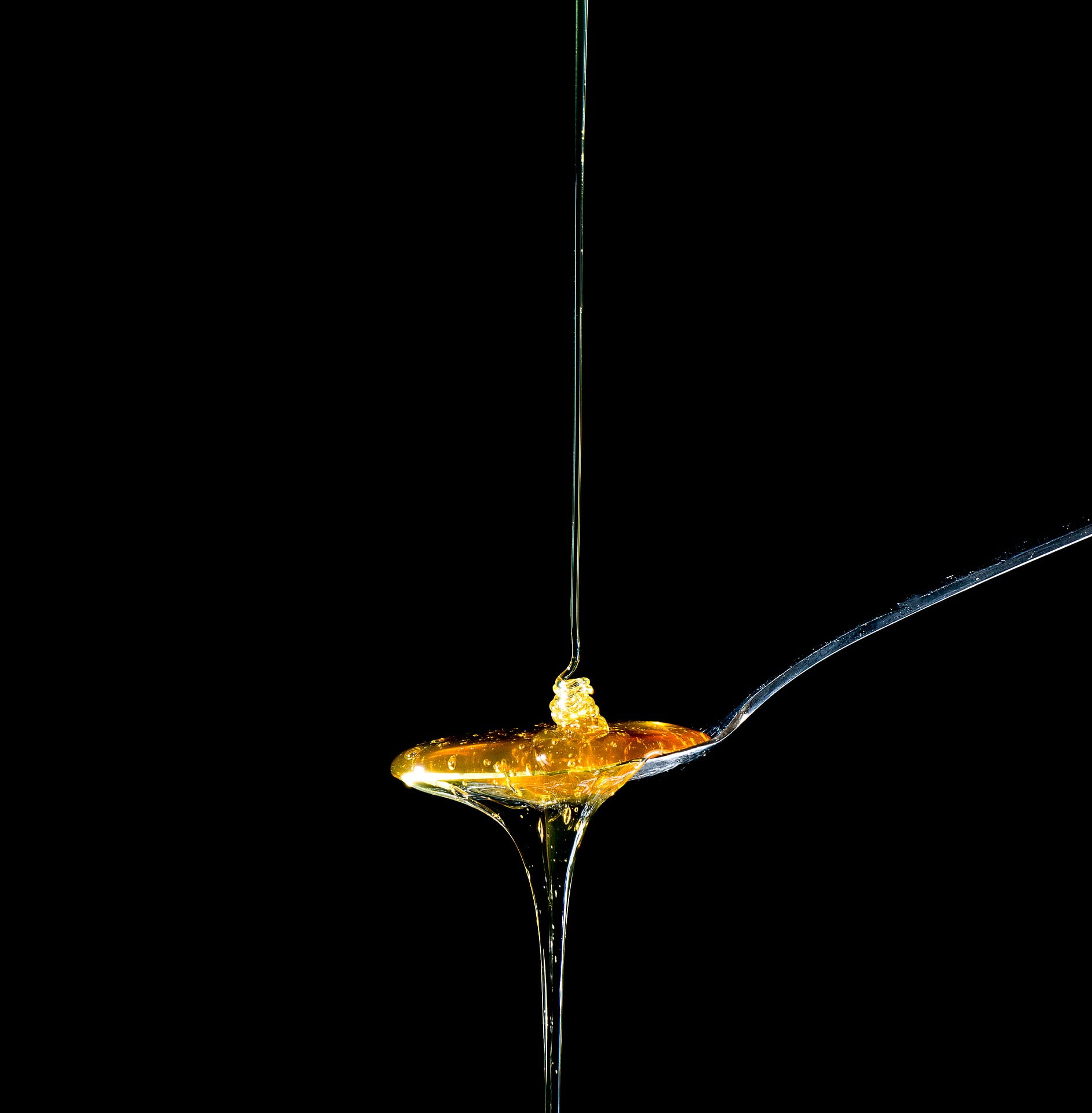

Viscoelastic Coiling

Drizzle honey or syrup from high enough, and you’ll see it coil like a liquid rope. This feature of viscous fluids also extends to polymer-filled viscoelastic fluids. But recent work shows that the elasticity of these fluids delays the onset of coiling; put differently, if you pour two fluids of comparable viscosity, the viscoelastic one will have to fall farther before it will start coiling. The authors also found that the coiling frequency for a viscoelastic fluid is smaller than a viscous one, given the same experimental conditions. (Image credit: flo222; research credit: Y. Su et al.)

Aging Fluids

If you’ve ever left a sealed container of Playdoh untouched for months, you know that there’s a big difference between the fresh stuff and what’s left in that can. Aging can have big effects on non-Newtonian fluids. In this video, we see drops of a synthetic clay impacting at different speeds. In the top row of images, the clay is fresh and unaged; on impact, the clay forms large crown-like splashes. In the bottom row, however, the aged clay behaves quite differently. Instead of a splash, the drops make more of a splat. (Image and video credit: R. Ewoldt et al.)

Sundews Weaponize Viscoelasticity

In nutrient-poor soils, carnivorous plants like the cape sundew supplement their diets by eating insects. To entice their prey, the cape sundew secretes droplets of sugary water. But unwary insects who land to feed soon find themselves unable to pull away from this viscoelastic liquid. Complex molecules in the fluid grant it elasticity, so when insects pull against it, the liquid stretches and pulls back instead of breaking up. Other carnivorous plants, like the pitcher plant, use similar non-Newtonian tricks to trap insects. (Video and image credit: Deep Look)

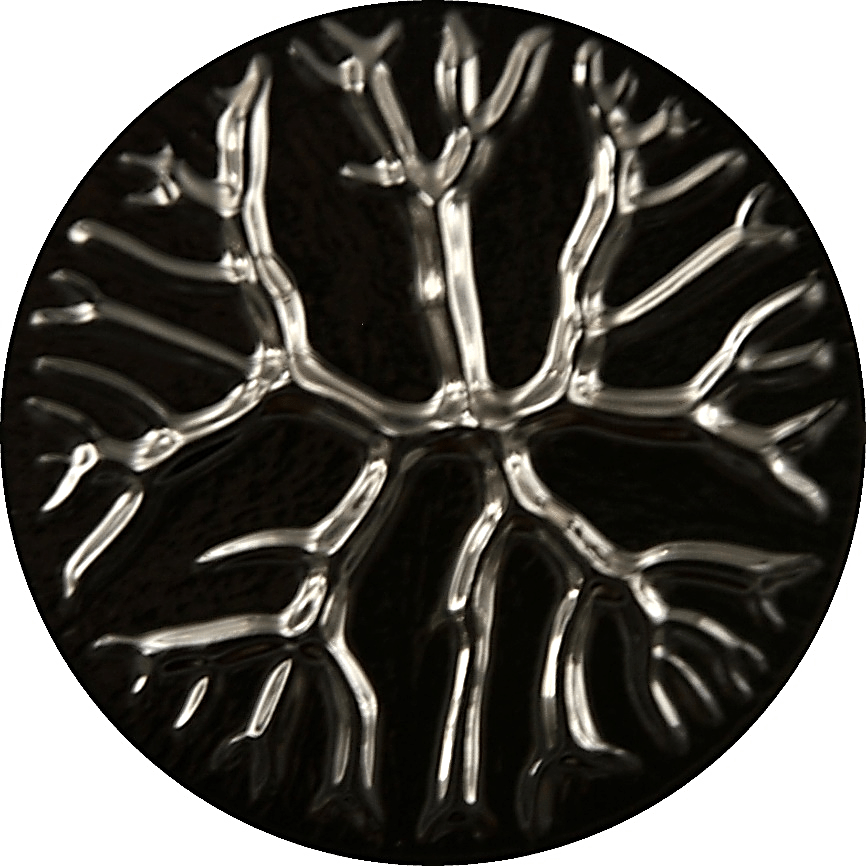

Branching Gels

If you sandwich a viscous fluid between two plates, then pull the plates apart, you’ll often get a complex branching pattern that forms as air pushes its way into the fluid. But the exact results depend strongly on what kind of viscous fluid you used. A new study looks specifically at what happens when that fluid is a yield-stress gel.

Yield-stress fluids behave like a solid until a critical amount of force causes them to flow. Think about your toothpaste. When you take the cap off, the toothpaste stays put until you squeeze the tube enough to make it flow. The gels used in this experiment behave similarly.

The researchers found that their gels required a critical energy input in order to branch and flow. If the energy applied in pulling the plates apart was too low, no branching occurred (Image 1). But beyond that critical energy, separating the plates created intricate branching patterns consistent with those seen in simpler, Newtonian fluids. (Image, research, and submission credit: T. Divoux et al.; via APS)

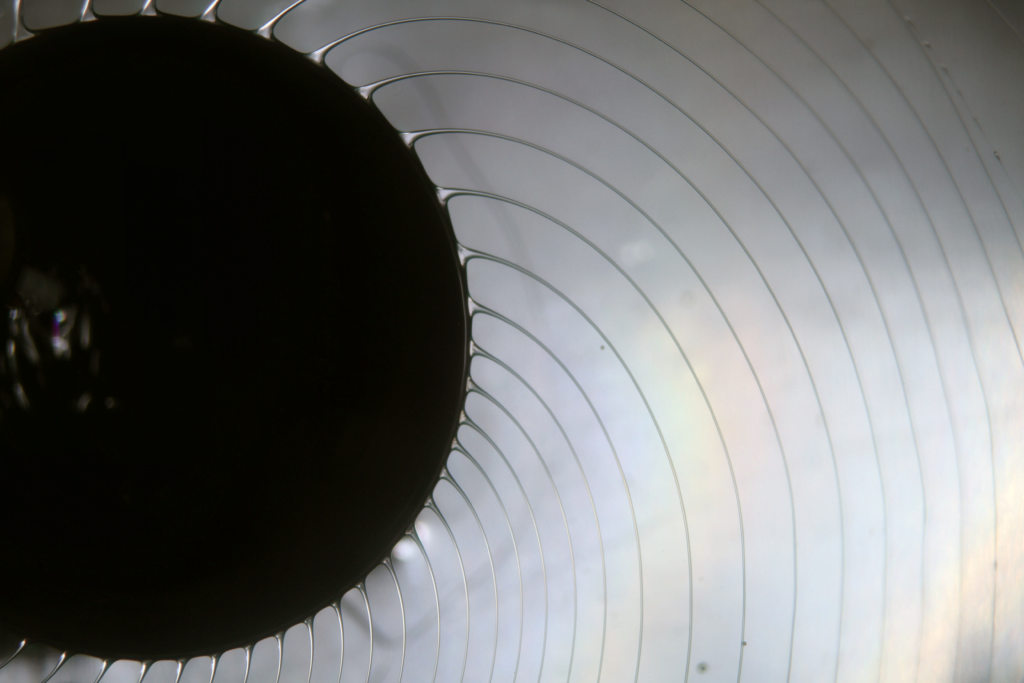

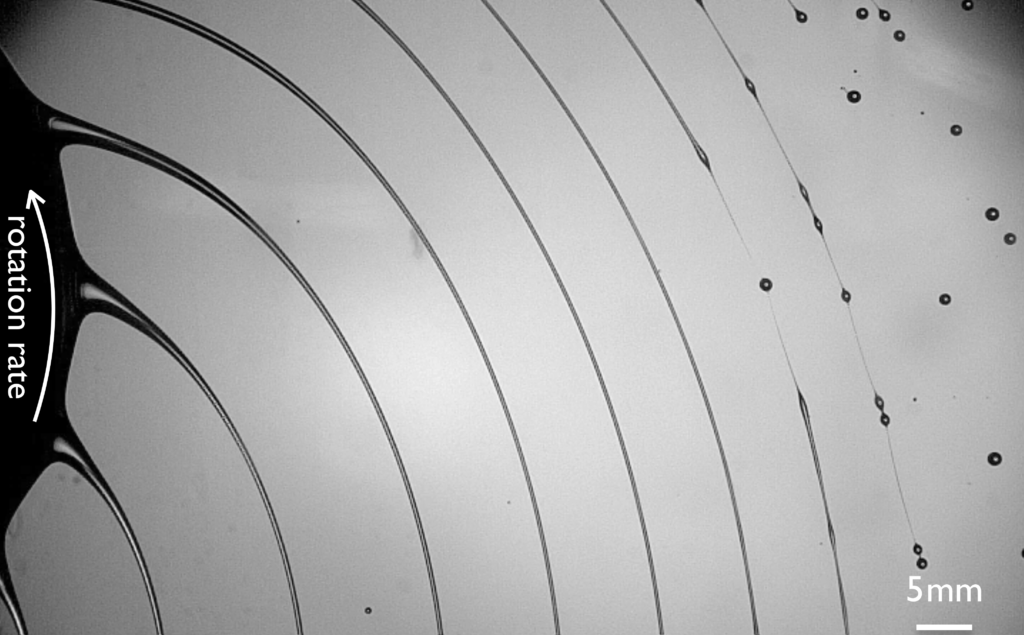

Spin Cycle

Rotational motion is a great way to break up liquids, as anyone who’s watched a dog shake itself dry can attest. That same centrifugal force is what allows this rotary atomizer to break liquids into droplets. Relative to the photos above, the atomizer spins in a counter-clockwise direction. This motion stretches the fluid flowing off it into skinny, equally-spaced ligaments, which eventually break down into droplets.

Just how and when that break-up occurs depends on the fluid, as well as the characteristics of the spin. For Newtonian fluids like silicone oil — shown in the first two pictures — the break-up is driven by surface tension and happens relatively quickly. But with a viscoelastic fluid — shown in the last image — the elasticity of polymers in the fluid allow it to resist break-up for much longer. Instead, the ligaments form the beads-on-a-string instability. See more flows in action in the video below. (Video, image, and research credit: B. Keshavarz et al., video)

Modeling Oobleck

Oobleck – that peculiarly behaved mixture of cornstarch and water – continues to be a favorite of children and researchers both. Oobleck flows like a liquid when deformed slowly, but try to move it quickly and it will seize up like a solid. This sudden change depends on the tiny particles of cornstarch suspended in the liquid. When they’re given time, electrostatic forces between the particles help them repel one another and keep the liquid flowing. But under sudden impacts, the particles get jammed together and the friction between neighboring grains makes the viscosity of the fluid increase by orders of magnitude.

Researchers are now able to model these particle interactions numerically, which will help them predict how oobleck and similar substances will behave in applications like body armor or pothole repair. (Video credit: MIT; via MIT News; research credit: A. Baumgarten and K. Kamrin)

Avoiding Shear Thickening

Many substances – like the cornstarch and water mixture above – exhibit a property called shear-thickening. In these fluids, deforming them quickly causes the viscosity to increase dramatically. That shear-thickening occurs when particles inside the fluid jam together, creating large chains able to resist the force being applied. That’s why the oobleck on this vibrating speaker can sustain these “cornstarch monsters”.

Shear-thickening is useful in many contexts, but it’s problematic during manufacturing, when pumping these substances can become incredibly difficult due to the fluid’s innate resistance to flowing. A new study, though, finds that it’s possible to temporarily suppress shear-thickening using acoustic waves. The researchers used piezoelectric devices to generate acoustic waves at a frequency around 1 MHz while shearing the cornstarch mixture. The acoustic waves disrupt the formation of particle chains inside the mixture, keeping its viscosity 10 times lower than during regular shear-thickening. (Image credit: bendhoward, source; research credit: P. Sehgal et al.; submitted by Brian K.)

Viscoelasticity and Liquid Armor

One proposed method for improving bulletproof armor is adding a layer of non-Newtonian fluid that can help absorb and dissipate the kinetic energy of impact. Thus far researchers have focused on shear-thickening fluids – like cornstarch-based oobleck – filled with particles that jam together if anything tries to deform them quickly. But is it really the shear-thickening properties that matter for high-speed impacts?

To test this, researchers studied projectile impact on three fluids: water (left), a cornstarch mixture (not shown), and a shear-thinning polymer mixture (right). Water is Newtonian, and it slows down the projectile but doesn’t stop it. Both the shear-thickening cornstarch and the shear-thinning polymer mixture do stop the projectile. And by modeling the impacts, researchers concluded that the key to that energy dissipation isn’t their shear-related behaviors: it’s the fact that both fluids are viscoelastic.

That means that these fluids show both viscous (fluid-like) and elastic (solid-like) responses depending on the timescale of an impact. The high speed of the impact triggered a strong viscous response in both fluids, bringing the projectile to a halt. And if, as the researchers suggest, it’s a fluid’s viscoelasticity that matters most, that widens the field of candidates when it comes to developing a fluid-based armor. (Image and research credit: T. de Goede et al.)

Oobleck Under Impact

Fluids like air and water are Newtonian, which means that the way they deform does not depend on how the force on them gets applied. Many other fluids, however, are non-Newtonian. How they behave depends on how force is applied to them. The Internet’s favorite non-Newtonian fluid is probably oobleck, a mixture of cornstarch and water with some fairly extreme properties. When deformed quickly, like when struck with a bat, oobleck doesn’t flow; it shatters.

What’s happening at the microscopic level is that the cornstarch particles in the oobleck are jamming together. They simply cannot move quickly and avoid one another. When they jam together, the friction between them goes way up and so does the apparent viscosity of the oobleck. Because it doesn’t have time to flow, all that energy goes into breaking off “solid” chunks instead. Once they hit the ground, the pieces of oobleck will puddle, just like any other liquid. (Image and video credit: Beyond the Press; via Nerdist)