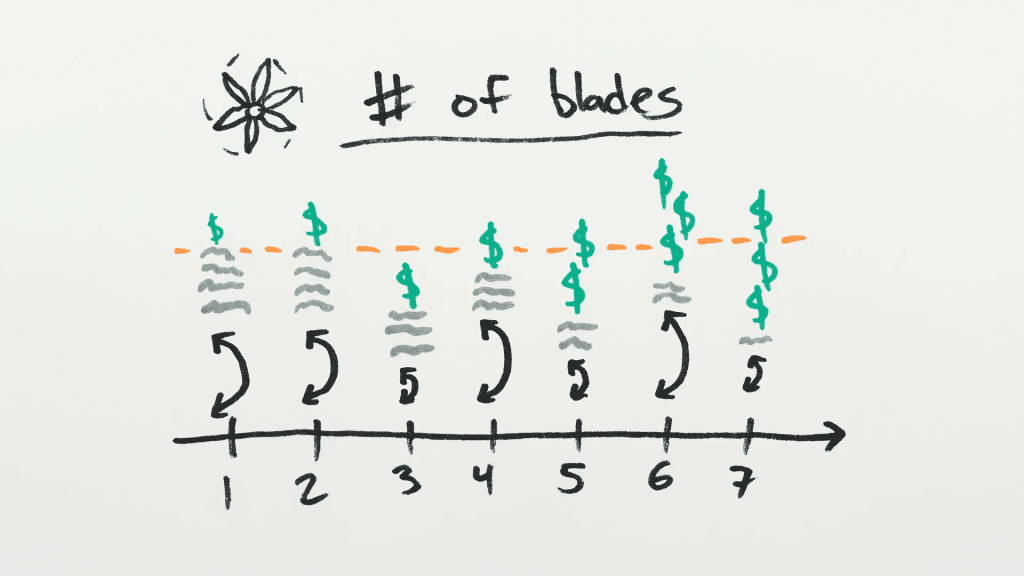

Although wind turbines can have any number of blades, most that we see have three. The reasons for that are many, as explained in this Minute Physics video. In terms of physics, wind turbines with more blades produce more torque, but they pay for it with more drag. Engineering-wise, wind turbines with odd numbers of blades have less uneven forces on them, and, thus, cost less. And, finally, people just prefer the look and sound of 3-bladed wind turbines over other forms! (Video and image credit: Minute Physics)

Tag: engineering

Protecting Wildlife from Underwater Construction

The loud noises of construction are not just an issue for humans. Sound and pressure waves from underwater construction are a problem for water-dwellers, too. So engineers use bubble curtains around a construction site to help reduce the amount of sound that escapes. Water and air transmit sound very differently; in acoustic terms, they have very different impedance. You’ve probably experienced this yourself if you’ve ever compared the sounds of a swimming pool above and below the surface. Because some of a sound’s intensity gets lost in the water –> air –> water transition, a bubble curtain can halve the sound pressure transmitted from equipment. (Video and image credit: Practical Engineering)

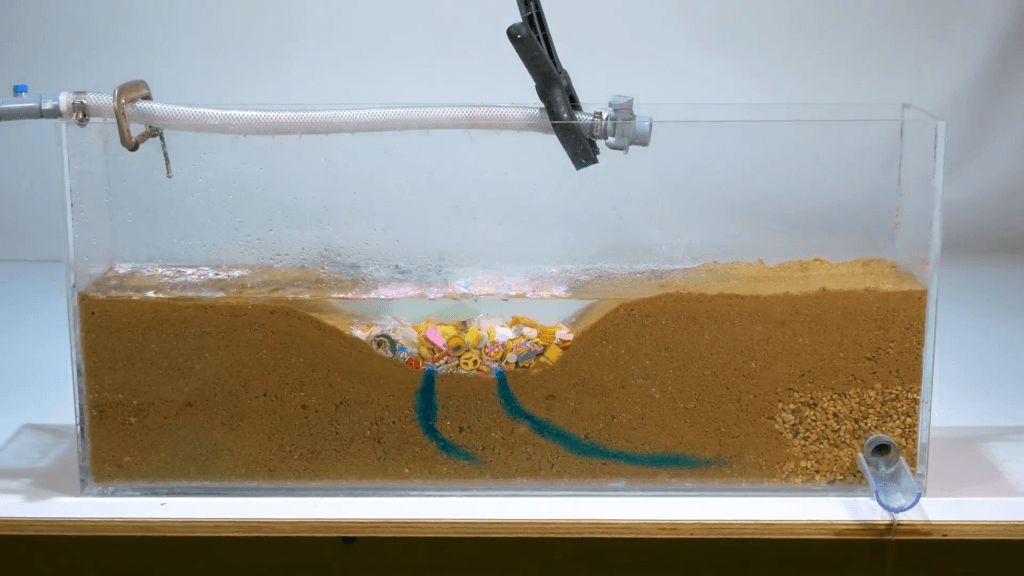

Dams Fill Reservoirs With Sediment

Dams are critical pieces of infrastructure, but, as Grady shows in this Practical Engineering video, they are destined to be temporary. The reason is that they naturally fill with sediment over time. Rivers carry a combination of water and sediment; the latter is critical to healthy shorelines and stable ecology. But while sediment gets carried along by a fast-flowing river, slower flow rates allow sediment to fall out of suspension, as demonstrated in Grady’s tabletop flume. As his river transitions to a deeper, slower-flowing reservoir, sand falls out of the flow, building up colorful strata. The sand and water even create dynamic feedback loops, as seen with the dunes that form in his timelapse and march toward the dam.

Any long-term plan for a dam has to deal with this inevitable build-up of sediment, and, unfortunately, it’s not a simple or cheap problem to address, as discussed in the video. (Video and image credit: Practical Engineering)

Derecho-Induced Skyscraper Damage

Derechos are short-lived, intense wind storms sometimes associated with thunderstorms. Last spring, such a storm passed through Houston, leaving downtown skyscrapers with more damage than a hurricane with comparable wind speeds. Now researchers believe they know why a derecho’s 40 meter per second winds can badly damage buildings built to withstand 67 meter per second hurricane winds.

In surveying the damage to Houston’s skyscrapers, the team noted that broken windows were concentrated in areas that faced other tall buildings. In a wind facility, the team explored how skyscrapers interfered with each other, based on their separation difference. They looked both at conditions that mimicked a hurricane’s winds as well as the downbursts — strong downward wind bursts — that are found in derechos.

The researchers found that downbursts in between nearby buildings caused extremely strong suction forces along a building’s face — even compared to the forces seen with higher hurricane-force winds. Currently, these buildings are designed for hurricane-like conditions, but the team suggests that — at least in some regions — designers will need to take into account how downburst wind patterns affect a skyscraper, too. (Image credit: National Weather Service; research credit: O. Metwally et al.; via Ars Technica)

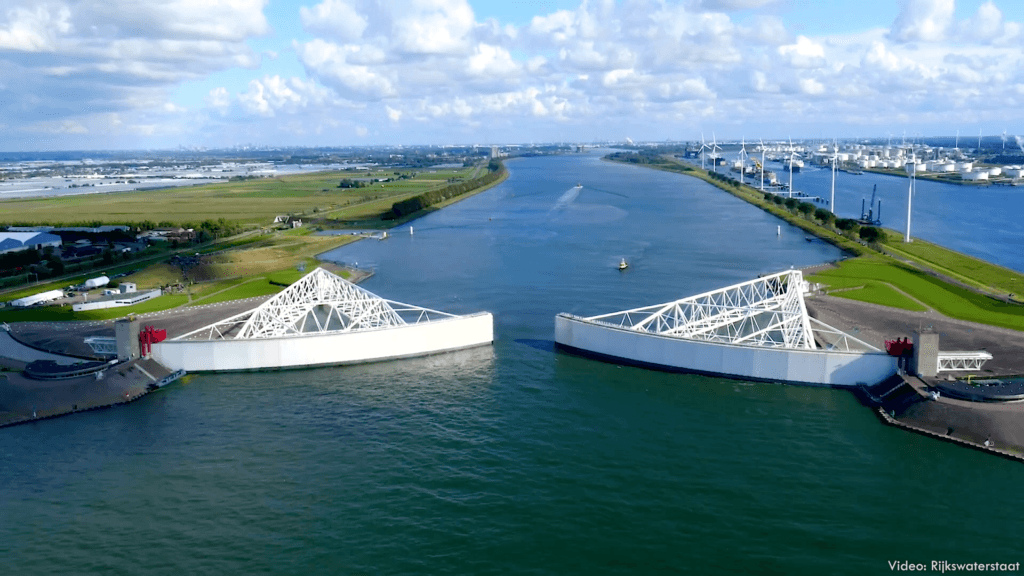

Dutch Water Works

The Netherlands have a long history of extraordinary public works when it comes to water management. With much of the country’s land lying at or below sea level, massive civil engineering infrastructure is a necessity. In this Practical Engineering video, Grady takes us on a tour of Dutch water works, from the centuries-old techniques that allowed farmers to claim arable land from marshes to the unbelievably massive structures that protect the Dutch coastline from flooding and storm surges.

For the Dutch, these projects, expensive as they are to build and maintain, are cheaper than the cost of inaction, as numerous devastating floods of the past have taught them. Although the goals are often the same — shortening the coastline, protecting land and people — the techniques are constantly evolving, especially as ecological needs of non-human species are taken into account. (Video and image credit: Practical Engineering)

How Cooling Towers Work

Power plants (and other industrial settings) often need to cool water to control plant temperatures. This usually requires cooling towers like the iconic curved towers seen at nuclear power plants. Towers like these use little to no moving parts — instead relying cleverly on heat transfer, buoyancy, and thermodynamics — to move and cool massive amounts of water. Grady breaks them down in terms of operation, structural engineering, and fluid/thermal dynamics in this Practical Engineering video. Grady’s videos are always great, but I especially love how this one tackles a highly visible piece of infrastructure from multiple engineering perspectives. (Video and image credit: Practical Engineering)

Engineering Our Landfills

We create a lot of waste and, at least for now, much of that waste goes into landfills. Properly managing garbage requires much more than digging a hole in the ground, as Grady from Practical Engineering shows in this video. Maintaining a landfill requires careful management of water, soil, landfill strata, and even gas buildup. And these challenges don’t end once the trucks stop arriving. Landfills require decades of care even after their closure. Check out the video to learn more about how these artificial structures are built, managed, and maintained. (Video and image credit: Practical Engineering)

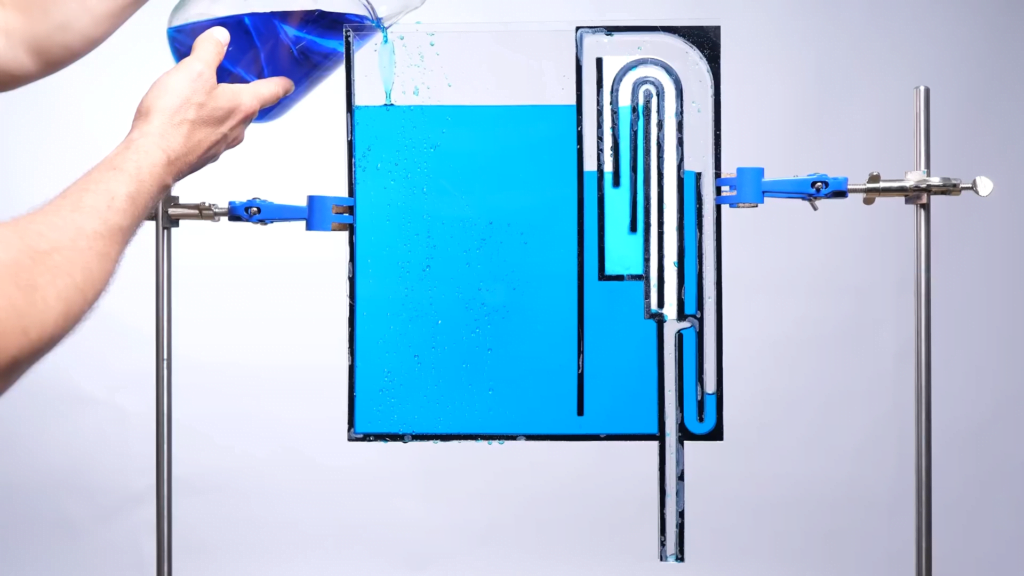

Breaking Down a Water-Powered Timer

In his latest “cutaway” video, Steve Mould takes a look at how you can nest siphons to create a system that periodically flushes itself. This kind of water-powered timer is useful in, say, public restrooms with a urinal system that collectively flushes every once in a while. In the video, Mould talks through each step of the system and some of the challenges he ran into when trying to create a pseudo-2D version of it. As is often the case with these videos, it’s a strangely satisfying process to watch. (Video and image credit: S. Mould)

Saving Screens with Shear-Thinning Fluids

These days glass screens travel with us everywhere, and they can take some big hits on the way. Manufacturers have made tougher glass, but they continue to look for ways to protect our screens. Recently, a study suggested that non-Newtonian fluids are well-suited to the task.

The team explored the physics of sandwiching a layer of fluid between a glass top layer and an LCD screen bottom layer, mimicking structures found in electronic devices. Through simulation, they searched for the fluid characteristics that would best minimize the forces felt by the solid layers during an impact. They found that shear-thinning fluids — fluids that, like paint or shampoo, get runnier when they’re deformed — provided the best protection. Having the impact energy go into reducing the local viscosity of the fluid stretches the length of time the impact affects the glass, which lowers the bending forces on it and helps avoid breakage. (Image credit: G. Rosenke; research credit: J. Richards et al.; via Physics World)

Liquid Metal Printing

Engineers have developed a new 3D-printing technique that uses molten aluminum to quickly manufacture large-scale parts. This Liquid Metal Printing method deposits the metal into a bed of tiny glass beads, which hold the metal in place while it cools. In minutes, they can produce furniture-sized parts, but that speed comes at a cost in resolution; the printed parts are rough, but they have the strength to withstand further machining by bending, milling, etc. The process is also well-suited for reusing scrap metal. The team hopes their method will be a useful prototyping tool as well as a possible manufacturing technique in architecture and construction. (Image and video credit: MIT News; research credit: Z. Karsan et al.)