Beer, soda, soap, meringue – foams are everywhere in our lives. But have you ever wondered why some foams disappear so quickly while whipped egg whites stick around? That’s the subject of this Gastrofisica video, which is in Spanish but has English captions.

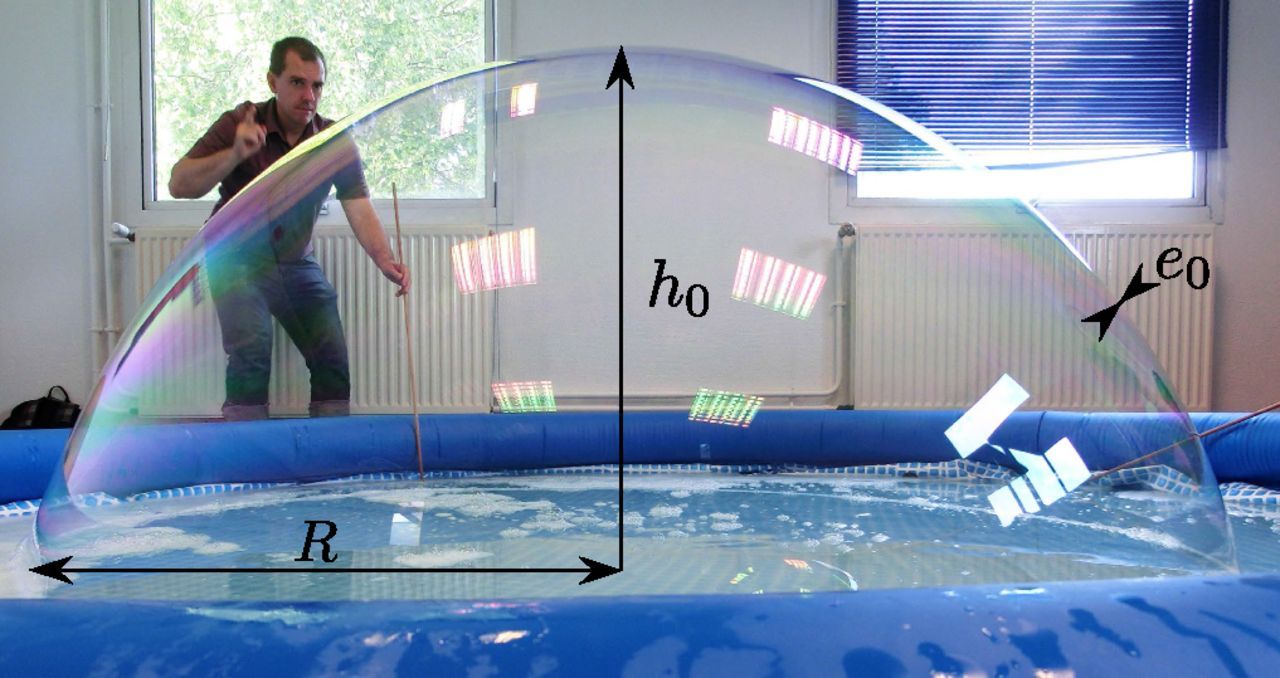

Foams form when air gets introduced into a liquid, but for those bubbles to stick around, they need a certain special something. With soapy water, that ingredient is surfactants, molecules with both hydrophobic (water-fearing) and hydrophilic (water-loving) ends, which line up at the interface of the foam and help hold it together. But surfactants are relatively weak, especially compared to to the albumin proteins in an egg white. By whipping egg whites, you’re effectively untangling those proteins, and, like surfactants, they line up at the interface of the foam so that their hydrophobic and hydrophilic parts can hang out in their preferred mediums. With so many similar molecules crowded together, the proteins coagulate, adding extra strength and stiffness to your whipped egg whites. (Video and image credit: Tippe Top Physics; h/t to MinutePhysics)