In 1756, Leidenfrost reported on the peculiar behaviors of droplets on surface much hotter than the liquid’s boiling point. Such droplets were highly mobile, surfing on a thin layer of their own vapor and were prone to loud cracking noises.

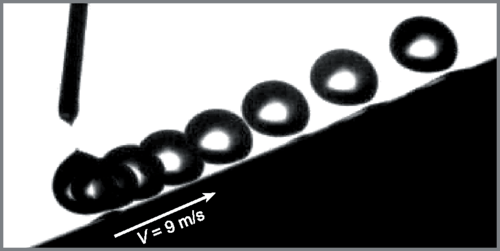

More recently, scientists have observed that drops with an initially small radius eventually rocket off the hot surface whereas larger drops end their lives in an explosion (above) – the source of Leidenfrost’s crack. Now researchers have explained why drops of different sizes have such different fates. The key is their level of contamination.

To reach the take-off radius, the drop has to evaporate a significant portion of its volume. For an initially-large drop, that’s tough because any solid contaminants in the drop will build up along the surface of the drop as it shrinks. Eventually, they restrict the liquid from evaporating, which thins the vapor layer the drop sits on. It sinks until a part of it touches the surface. The sudden influx of heat from the surface explosively destroys whatever remains of the drop. (Image and research credit: S. Lyu et al.; via Brown University; submitted by gdurey)