Steve Mould is back with another video looking at wild fluid behaviors. This time he’s considering hose instabilities like the one that makes a water-carrying hose beyond a certain length to whip wildly back and forth. He tries to track down the reasoning for these flexible hoses snapping and whipping. In truth, both the hoses and the wind dancers do their thing due to interactions between the elasticity of the hose and the fluid dynamics of the flows within. These applications are ripe for a few control volume thought experiments. (Video and image credit: S. Mould)

Tag: elasticity

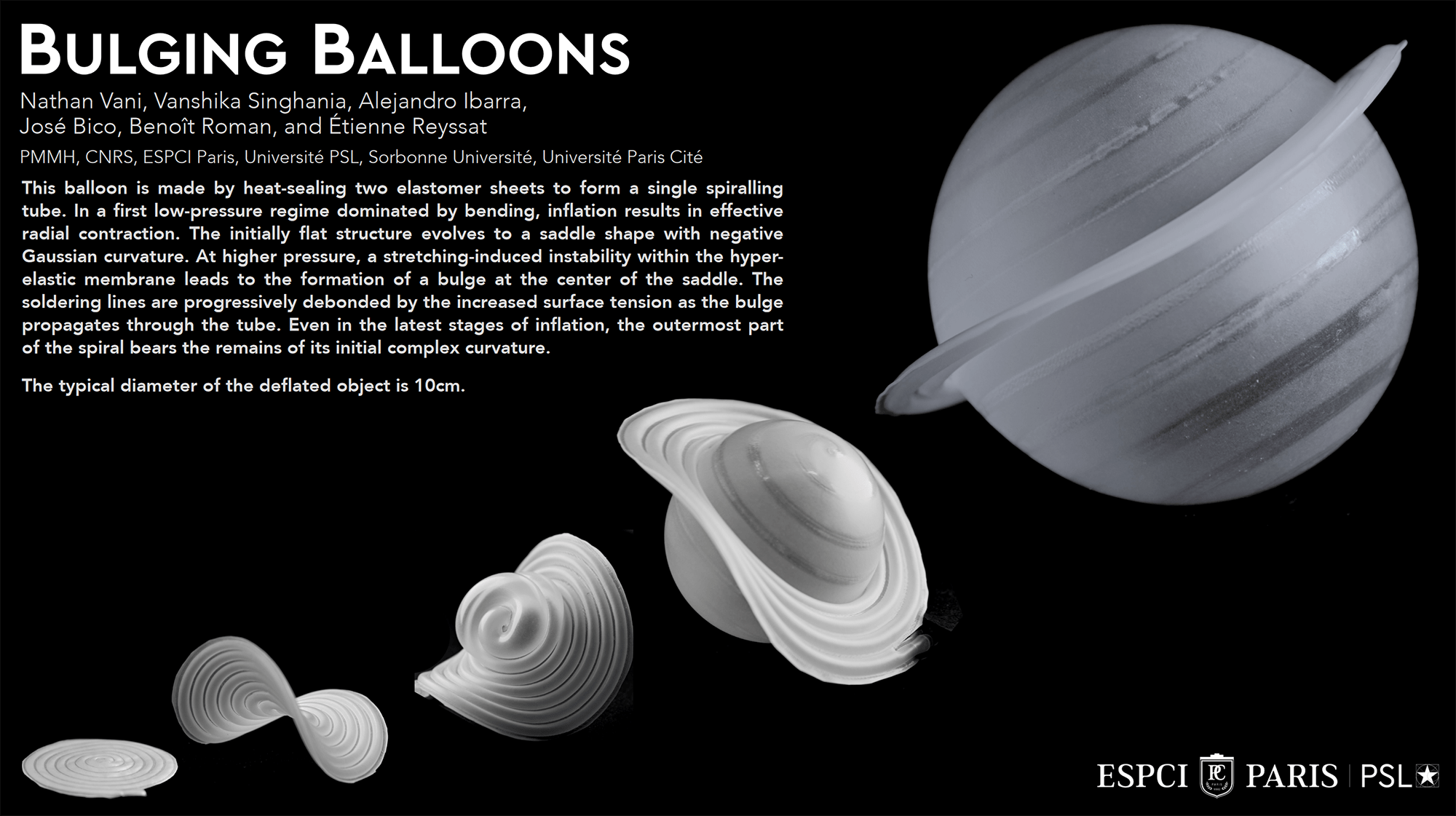

“Bulging Balloons”

This planet-like balloon started out as two elastomer sheets, heat-sealed together into a spiraling tube. As the balloon was inflated, it changed from flat to a saddle-like shape. With more air, the pressure inside increased, triggering an instability that caused the middle of the balloon to bulge. As inflation continued, the central bulge expanded, unbonding layer after layer of the seal. Even late in inflation, the balloon maintains hints of its original shape in the form of a ring around the Jovian bulge in the middle. (Image credit: N. Vani et al.)

Lasers and Soap Films

Soap films are a great system for visualizing fluid flows. Researchers use them to look at flags, fish schooling and drafting, and even wind turbines. In this work, researchers explore the soap film’s reaction to lasers. When surfactant concentrations in the soap film are low, laser pulses create shock waves (above) in the film that resemble those seen in aerodynamics. The laser raises the temperature at its point of impact, lowering the local surface tension. That temperature difference triggers a Marangoni flow that draws the heated fluid outward. The low surfactant concentration gives the soap film relatively high elasticity, and that allows the shock waves to form.

In contrast, a soap film with a high concentration of surfactants has relatively little elasticity. In these films (below), the laser creates a mark that stays visible on the flowing soap film. This “engraving” technique could be used to visualize flow in the soap film without using tracer particles. (Image and research credit: Y. Zhao and H. Xu)

When surfactant concentrations are high, a laser pulse “engraves” spots onto a flowing soap film. Shown in terms of interference (left) and Schlieren (right) imaging.

Bending in Bubbles

Inside a cavity with a square cross-section, bubbles form an array. The shapes of their edges are determined by surface tension and capillarity (lower half of center image). Adding an elastic ribbon into the bubbles (upper half of center image) means that the bubbles’ shapes are determined by a competition between the elasticity of the ribbon and the capillarity of the fluid. Researchers found that they could tune the rigidity of the ribbon to dictate the shape of the bubble array, or, conversely, they could use the bubbles to set the shape of a UV-curable ribbon. (Image and research credit: M. Jouanlanne et al., see also)

Leaping Hoops

Some water-walking insects are able to leap off a watery interface. One way to model these creatures is with elastic hoops, which can also propel themselves off the water’s surface. In this video, researchers explore some of the factors that affect the jump, like hoop geometry, material, and hydrophobic coatings. Wider hoops jump better than thinner ones because they can store more elastic energy. Hydrophobic hoops also leap higher, because less energy gets wasted in splash creation. Since most water-walking insects have hydrophobic legs already, that’s a bonus for jumping off the surface! (Image, video, and research credit: H. Jeong et al.)

Capsule Impact and Bursting

Nature and industry are full of elastic membranes filled with a fluid, from red blood cells to water balloons. A new study looks at how these capsules deform — and sometimes burst — on impact. The researchers created custom elastic shells that they filled with various fluids like water, glycerol, and honey, then used the impacts to build a model of capsule deformation.

They found that there’s significant overlap between droplet impacts and capsule impacts, with a few key differences; instead of surface tension, capsules resist deformation through their elastic shell’s surface modulus — a combination of its elasticity and thickness. Capsules, unlike droplets, can also burst. To study this, the researchers used water balloons, which they were able to pre-stretch more easily than their custom shells. They found that their model could accurately predict the conditions under which the balloons burst.

The authors hope the model will be helpful both in designing capsules intended to burst — like a fire-fighting projectile — and in creating safety measures to prevent capsule burst — like car-crash standards that protect from organ damage. (Image and research credit: E. Jambon-Puillet et al.; via Physics World; submitted by Kam-Yung Soh)

Plant Week: Bunchberry Dogwood

The bunchberry dogwood, unlike its taller relatives, is a low-lying subshrub that spreads along the ground. But it sports some of the fastest action of any plant, requiring 10,000 frames per second to capture! When young buds form in the bunchberry flower, their four petals are fused, completely hiding the stamens. As the plant matures, the pollen-carrying stamens grow faster than the petals, causing them to peek out the sides of the bud. But the petals stay attached at the tip, holding the stamens in while pressure inside the stamens creates a store of elastic energy.

When disturbed, the petals break loose and the stamens spring up and out. The anthers at their tips hold the pollen in place until the stamen reaches its maximum vertical velocity, at which point the anthers swing out to release the pollen upward. In essence, the flower works in the same manner as a trebuchet, flinging pollen with an acceleration 2,400 times greater than gravity. That’s enough to coat pollen onto nearby insects and to launch the remainder high enough for the wind to catch it. (Image and research credit: D. Whitaker et al., source; via Science News; submitted by Kam-Yung Soh)

And with that, FYFD’s Plant Week is a wrap! Missed one of the previous posts? You can catch up with them here.

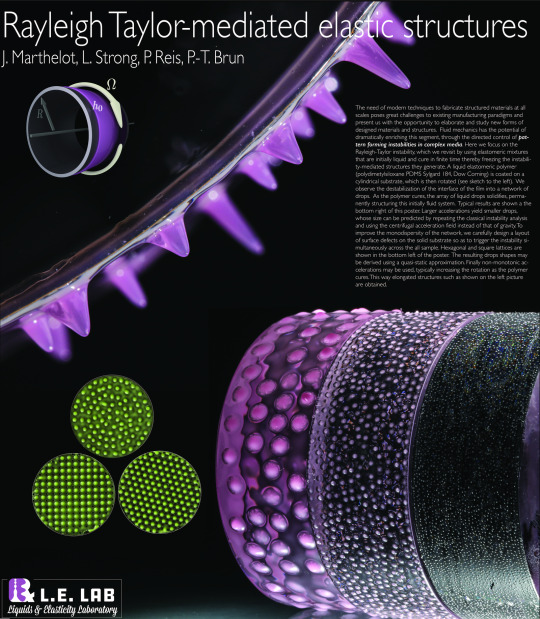

Using Instabilities for Manufacturing

Manufacturing textured, flexible surfaces can be difficult, but researchers are exploring ways to use fluid dynamical instabilities to make the process easier. They begin with a pourable polymer mixture that cures and solidifies over time. By putting the mixture on a cylinder and rotating it, engineers trigger the Rayleigh-Taylor instability – the same instability that makes dense fluids sink into lighter ones. Here, the instability is driven not only by gravity but by the added acceleration caused by centrifugal force. It causes the fluid film to drain and form arrays of droplets, which then cure into dimples. The researchers can control the size, shape, and spacing of the droplets by changing parameters like the spin rate. And by repeating the process multiple times on the same piece, they can build up spikier shapes, like the ones shown on the poster below. (Image and research credit: J. Marthelot et al., poster)

Reminder for those at the APS DFD meeting! My talk is tonight at 5:10PM in Room B206. You’ll probably want to come early if you want a seat!

Stopping a Bounce

One way to damp a bouncing ball is to partially fill it with a fluid (a) or granular material (b). For the fluid, the initial impact sloshes the liquid. That doesn’t change the trajectory of the initial bounce noticeably, but it interferes with the second impact, drastically damping the rest of the ball’s bounces until it comes to a stop. A grain-filled ball is similar, at least to begin with. The initial bounce sends the grains flying, forming a granular gas inside the ball. This doesn’t affect the trajectory of the first bounce, but the second impact collapses the granular gas. All the impacts of the grains with one another dissipate the energy of the bounce, and the ball comes to a complete stop. This suggests that a partially-grain-filled container can make a good damper in sport or industrial applications. It also suggests that it might be even better for water-bottle flipping than water is. (Image and research credit: F. Pacheco-Vázquez & S. Dorbolo)

Elastic Bounces

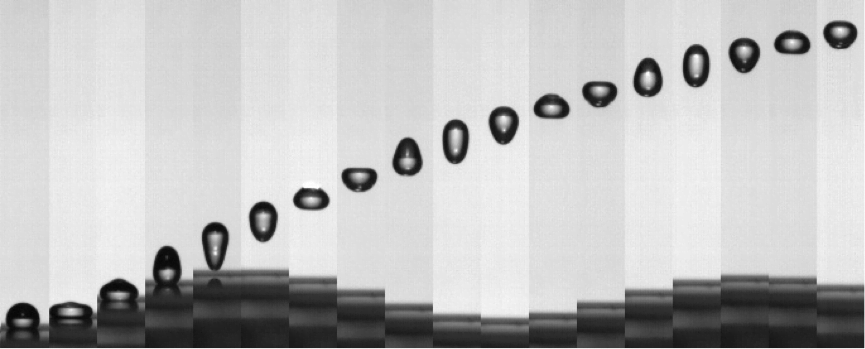

A rigid ball accelerated by a moving surface can only ever move as fast as the surface propelling it. But that’s not true for squishy objects like a water droplet. The composite image above shows the trajectory of a water droplet launched from a moving superhydrophobic surface. As the surface starts rising, it squishes the droplet like a pancake, triggering a deformation cycle where the droplet will squish and extend repeatedly. How quickly the drop changes shape depends on factors like its size and surface tension. The researchers found that a droplet’s launch was strongly affected by the ratio of the droplet’s shape-changing frequency and the frequency of the plate’s motion. When the drop’s shape changed three times faster than the surface’s motion, it would catapult off the surface with 250% of the kinetic energy of a rigid ball!

Launching elastic balls works the exact same way as droplets, indicating that the phenomenon depends on the way the projectiles deform. The process is similar to jumping on a trampoline. If a trampolinist times her jump just right, she’ll get more energy from the trampoline and fly higher. The droplet does the same when its deformation is properly tuned to its catapult. (Image credit: C. Raufaste et al.; via APS Physics; submitted by Kam-Yung Soh)