Ever wonder how a gas pump shuts off when the tank is full? You might guess that there’s a sophisticated electronic sensor hidden in there. But there isn’t! Gas pumps use an entirely mechanical technique to sense a full tank and shut off flow, as Steve Mould demonstrates in this video.

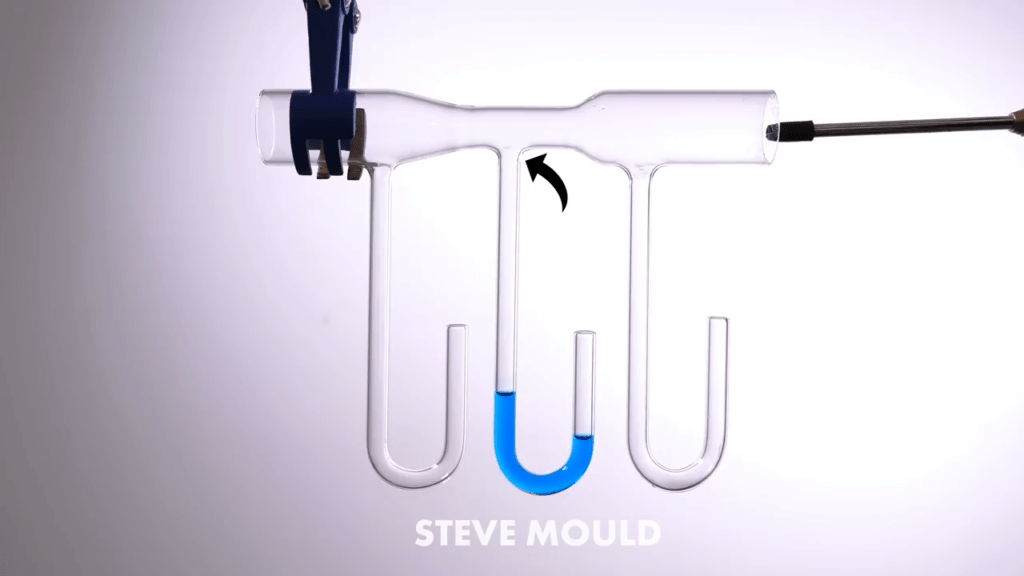

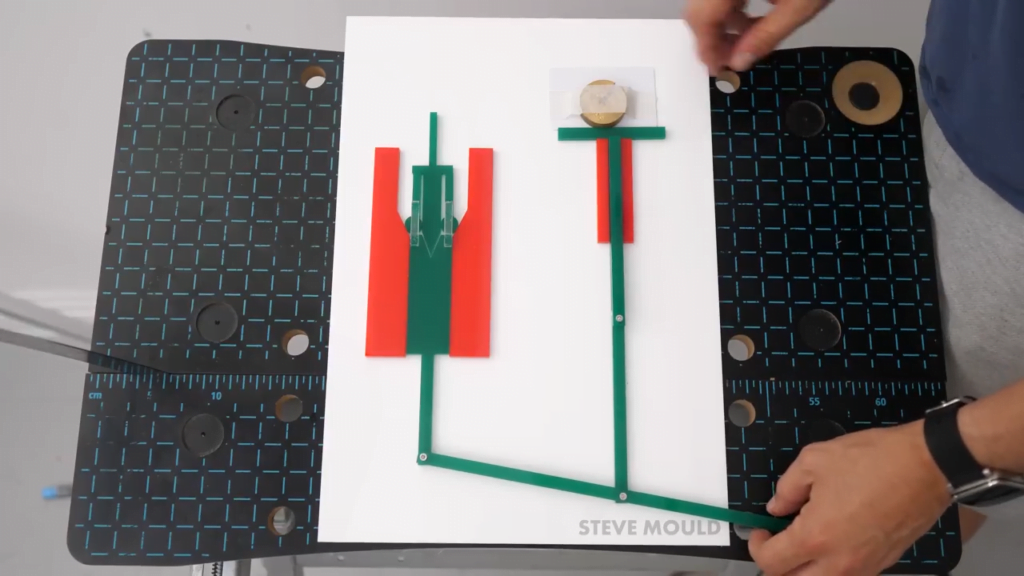

There are two key components — one fluid mechanical and one based on mechanical linkages — inside the handle. The part that senses a full tank is a Venturi tube, shown in Image 2. The top section of the Venturi tube contains a constriction, where (incompressible) flow is forced to speed up. That increase in speed creates a drop in pressure, which is reflected by the movement of the water in the curved tube below the constriction.

Notice that when there’s no flow through the top tube, the water level is equal on either side of the lower, curved tube. That means that the outside air pressure (connected to the short arm) equals the pressure in the constriction (connected to the long arm). When air is flowing through the constriction, the water level shifts. The water in the short arm gets pushed down while the water in the long arm gets sucked up. That change means that the air pressure outside the tube is now higher than pressure in the constriction.

I’ll let Steve explain what that means for the gas pump! (Image and video credit: S. Mould)

Leave a Reply