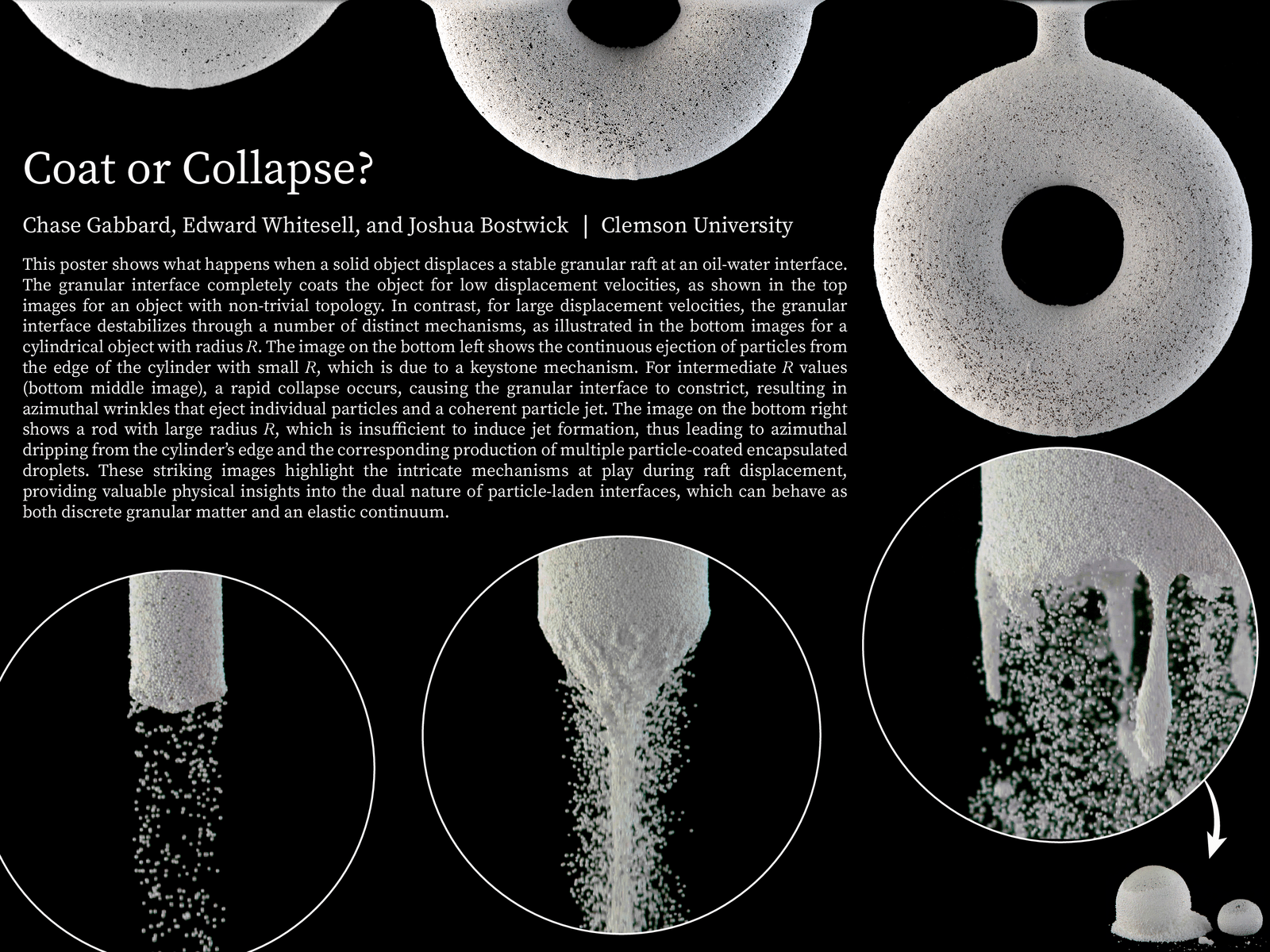

Imagine a layer of particles sitting at the interface between oil and water. Known as a granular raft, these particles can interact in interesting ways with other objects. Here, researchers experiment with allowing different shapes to fall through the raft. At slow speeds, the raft deforms to coat the object, even if it has a complex shape (top images). At higher insertion speeds, however, the granular raft can break up around the object. The lower sequence of images show a cylinder interacting with the raft. Moving from left to right, each image shows a larger cylinder diameter and an increasingly complex break-up of the raft. (Image credit: C. Gabbard et al.)

Tag: coating flow

Particle-Filled Coatings

Pulling a solid object from a liquid bath can coat it in a thin layer of liquid. The thickness of the coating layer depends on the speed at which the object is removed. Introducing particles into the liquid bath adds a new dimension to the coating problem, namely the size of the particles. In this poster, researchers demonstrate some of the coatings possible in a mixture with particles of more than one size. It’s even possible, they note, to filter out particles of a certain size by carefully selecting the removal speed. (Image credit: D. Jeong et al.)

Spin Coating Capillary Tubes

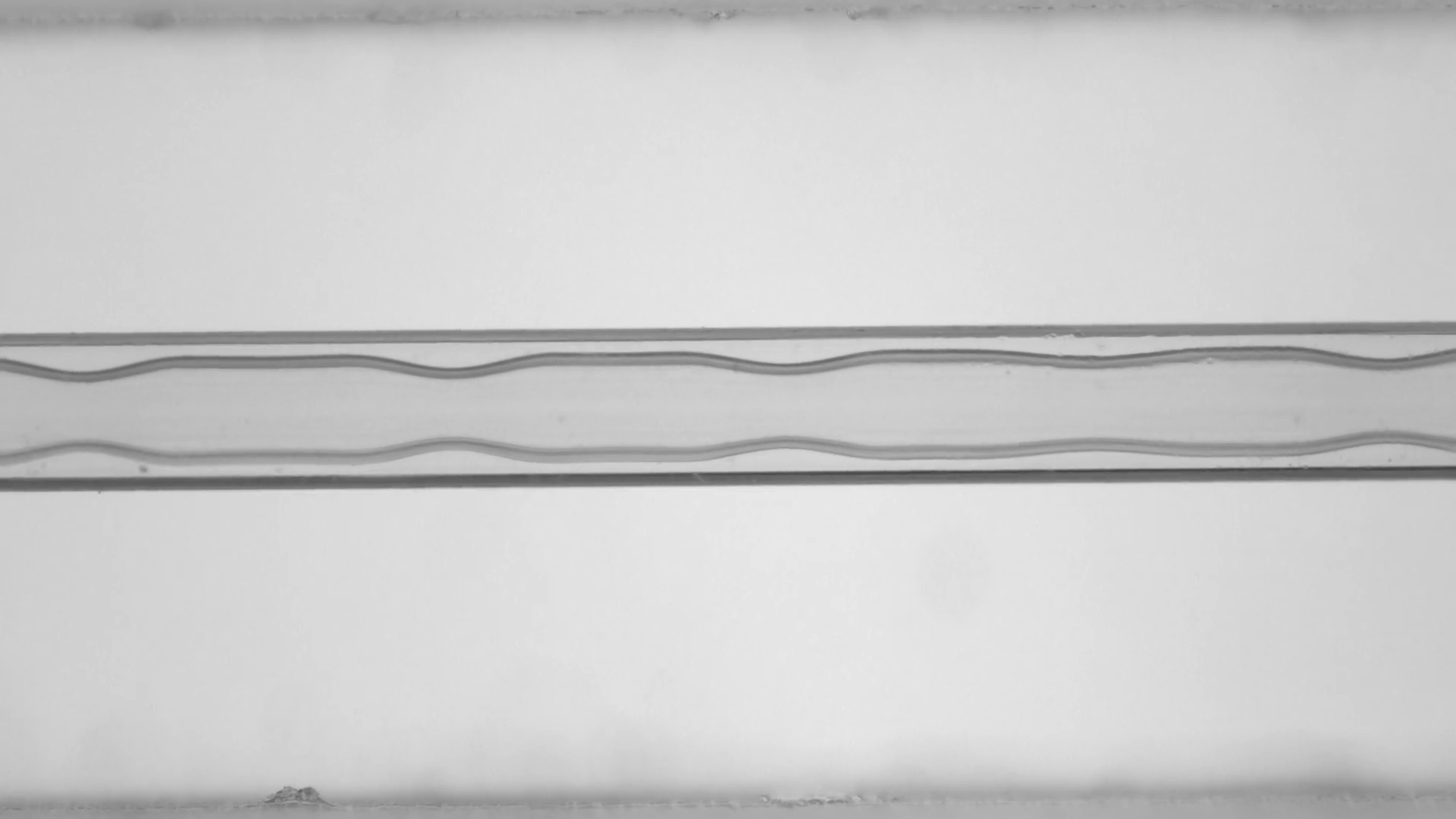

To coat the interior of a capillary tube, you typically fill the tube with a viscous liquid, then pump air in to displace the liquid, leaving behind a thin film of the viscous fluid. Keeping that film uniform and thin is a challenge, though, since the pumps used often struggle to keep a consistent low flow rate. Instead, a team of researchers used spin coating to treat the interior of capillary tubes.

Their apparatus consisted of a repurposed computer fan, stripped of its blades and fitted with a 3D-printed platform that could hold capillary tubes (left). When spinning, an oil slug inside each tube gets forced outward from the center of the platform, leaving behind a thin, uniform film coating in the tube. The group found that some fluids develop a wavy, Plateau-Rayleigh instability in the film once spinning stops (right), which is useful for creating a consistent wavy interior for the tube, particularly when using curable polymers for the coating. (Image, research, and submission credit: B. Primkulov et al.)

Shark Tooth Instability

Imagine that you partially fill a horizontal cylinder with a viscous fluid, like corn syrup or honey. If that cylinder is still, the fluid will simply pool along the bottom. On the opposite extreme, if you spin it very fast, that cylinder will become coated in an even layer of fluid that rotates along with the cylinder thanks to centrifugal force. Between those two extremes in rotational velocity, some interesting fluid behaviors occur. Start spinning the cylinder and some of the pooled fluid will be pulled up the sides, eventually forming a thicker film with a straight front along the bottom of the cylinder. Spin faster and that straight front starts to break down, forming sharper cusp-like waves known as shark teeth. (Image credit: S. Morris et al., source; research credit: S. Thoroddsen and L. Mahadevan)

Shark-Tooth Instability

A viscous fluid inside a horizontally rotating circular cylinder forms a shark-tooth-like pattern along the fluid’s free surface. This is one of several patterns observed depending on the fluid’s viscosity and surface tension and the rotational rate of the cylinder. (Photo credit: S. Thoroddsen and L. Mahadevan; for more, see Thoroddsen and Mahadevan 1996 and 1997)