An ultrasoft viscoelastic fluid drips in this research poster from the Gallery of Soft Matter. Complex materials like this one have stretchy, elastic behaviors typical of a solid along with the flowing, viscous properties of a fluid. Here, gravity overcomes the material’s elasticity, leaving it to sag and flow. As that happens, the fluid must slide past air, and the density difference between the two fluids creates the small distortions seen on the liquid sheet. This is an example of a Rayleigh-Taylor instability. (Image credit: J. Hwang et al.)

Tag: 2024gosmp

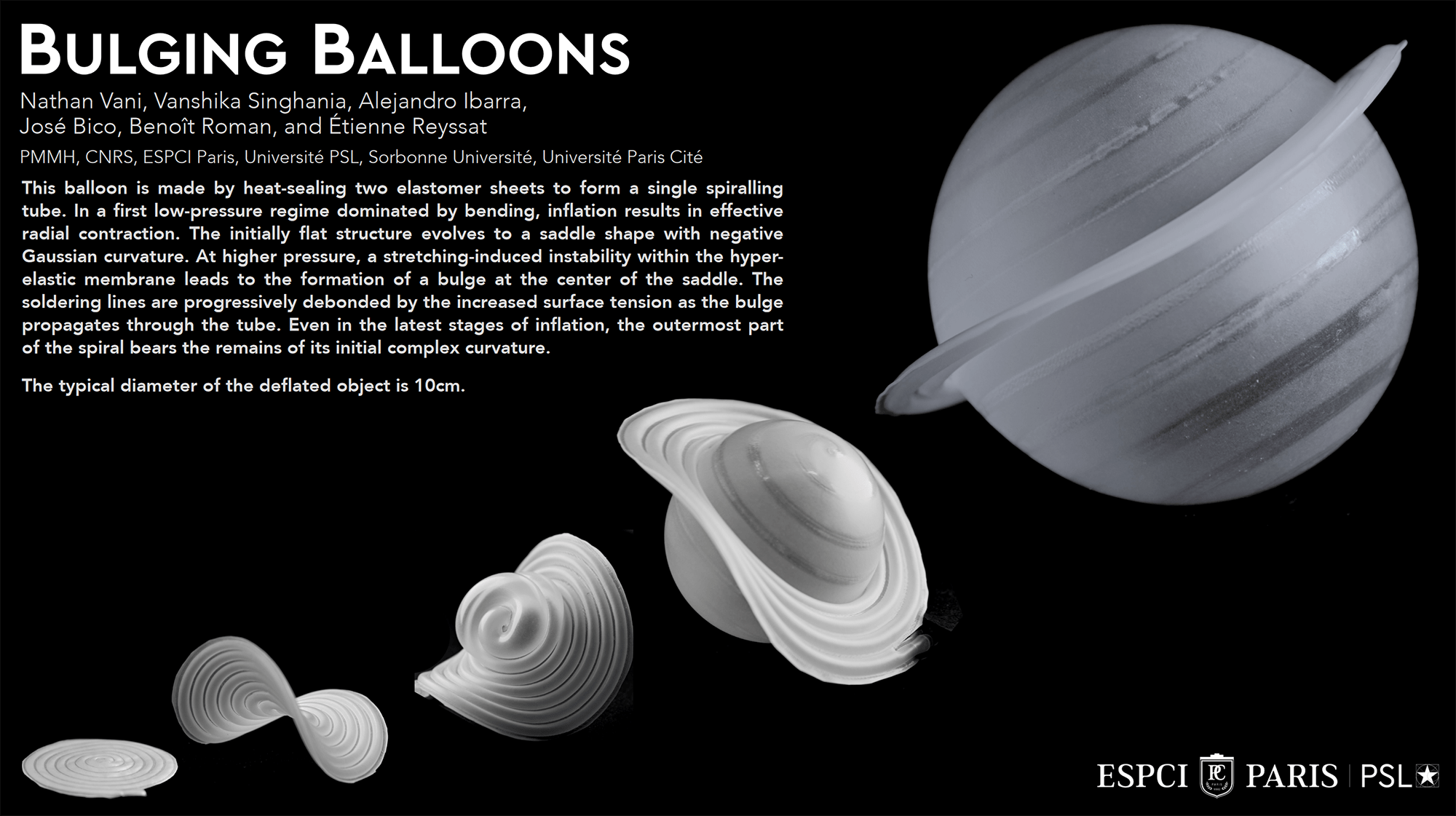

“Bulging Balloons”

This planet-like balloon started out as two elastomer sheets, heat-sealed together into a spiraling tube. As the balloon was inflated, it changed from flat to a saddle-like shape. With more air, the pressure inside increased, triggering an instability that caused the middle of the balloon to bulge. As inflation continued, the central bulge expanded, unbonding layer after layer of the seal. Even late in inflation, the balloon maintains hints of its original shape in the form of a ring around the Jovian bulge in the middle. (Image credit: N. Vani et al.)

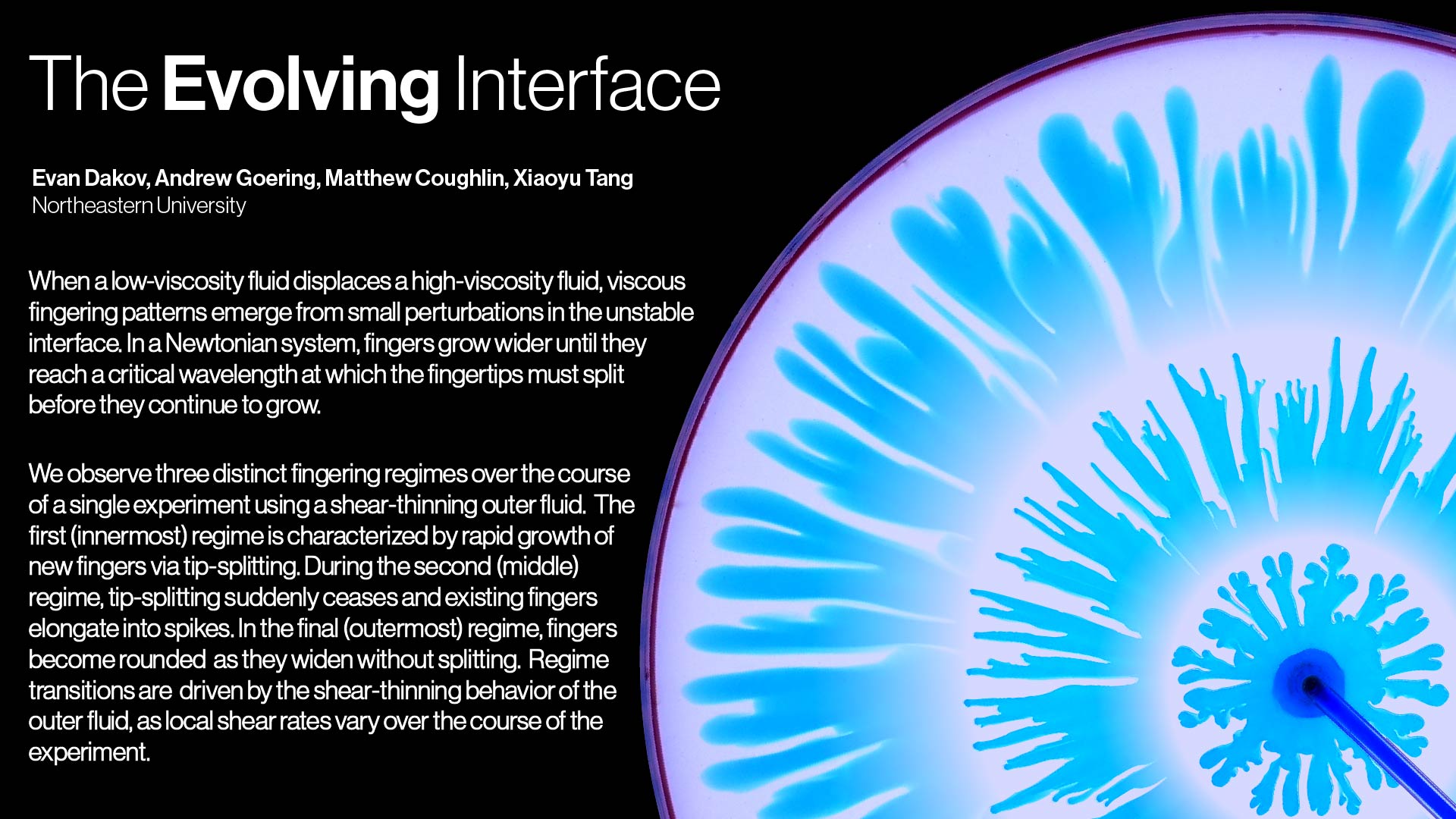

Evolving Fingers

If you sandwich a viscous fluid between two plates and inject a less viscous fluid, you’ll get viscous fingers that spread and split as they grow. This research poster depicts that situation with a slight twist: the viscous fluid (transparent in the image) is shear-thinning. That means its viscosity drops when it’s deformed. In this situation, the fingers formed by the injected (blue) fluid start out the way we’d expect: splitting as they grow (inner portion of the composite image). But then, the tip-splitting stops and the fingers instead elongate into spikes (middle ring). Eventually, as the outer fluid’s viscosity drops further, the fingers round out and spread without splitting (outer arc of the image). (Image credit: E. Dakov et al.; via GoSM)

Mimicking Plant Movement

Many plants control the curvature of their leaves by selectively pumping water into cells that line the outer surface. This swelling triggers bending. Engineers created their own version of this structure by 3D-printing trapezoidal shapes onto a fabric. Then, they heat sealed a second layer of fabric over this, creating airtight channels. When inflated, these channels make the structure bend, allowing them to create complex shapes by selectively inflating different areas. (Image credit: T. Gao et al.; via GoSM)